Electrophysical Technologies Commercialization

Limited liability company

«Sarov magnetic technology»

Contacts:

e-mail: sarmt@mail.ru

phone: +7-9107982473

About company:

The small enterprise was created in 2010. Experts with a great experience in pulsed

high and ultrahigh magnetic field technologies form the scientific team. Operations

of the company are closely related to activities of the High magnetic field laboratory

SarFTI NRNU MEPhI.

Products and activities:

-Manufacture of pulsed high magnetic field solenoids up to 60 T for scientific researches

and technological applications

- Spiral (beryllium bronze), wire (microcomposite Cu-Nb wire) and single-turn coils

- Developments of pulsed electromagnetic forming techniques

- Measuring techniques for pulsed high magnetic fields

- Design and manufacture equipment for pulsed high magnetic field facilities (solenoids,

power sources, switches, control systems)

- Pulsed high magnetic field and pulsed power engineering and consulting

Inverse frequency magnetic-pulsed technology

Magnetic-pulsed technology of materials processing (punching and welding) is based

on effect of ponderomotive forces on a conducting blank in pulsed magnetic field

(I.V.Beliy, S.M.Fertik, L.T.Khimenko Reference book on magnetic-pulsed processing,

Kharkov, Vischa Shkola, 1977).

At the expense of high-speed deformation, it is possible to create forms of punched

items, which can not be done by means of ordinary mechanical pressing and punching.

Magnetic welding allows reliably connecting manifold materials like copper-aluminum,

steel-aluminum. These could not be done using usual welding methods.

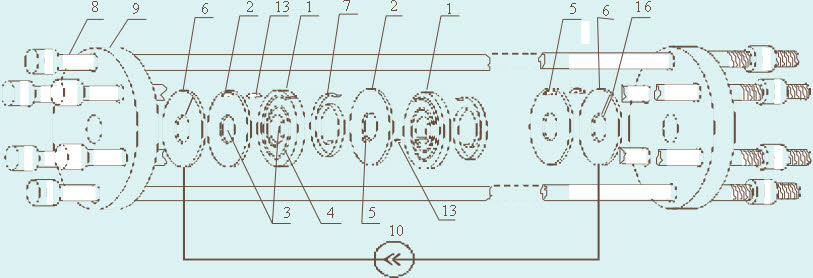

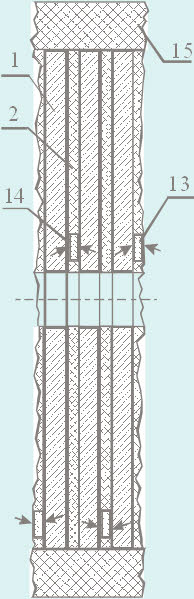

Inverse magnetic-pulsed technology

This is complicated variant of magnetic-pulsed technology. Firstly, a pulse of slow

initial magnetic field is created in the area of metal sheet (pulse length should

be sufficient for the magnetic field penetration through the sheet). Afterwards,

a short pulse of the secondary magnetic field of inverse direction is created (the

pulse is short enough, and the magnetic field can not penetrate through the metal

sheet). The ponderomotive force, appeared in these conditions, attracts the sheet

to the magnetic field source. This technology has commercial application in the USA.

It is used for unbending deformed aluminum elements of aircrafts.

Frequency inverse magnetic-pulsed technology

In the Invention Application ¹ 2013108334 in Russian Federation we suggest using

the series of secondary magnetic field pulses instead of a single pulse. Technical

result lies in decreasing voltage amplitude, which appears at secondary current flow

through the electromagnetic system. This allows fabricating a working head of the

device in a more compact and reliable way. Besides, voltage amplitude decrease allows

creating the device and method for unbending and removing defects of low-conducting

materials, like steel sheets of vehicles bodies.

This technology is being developed by “SarMT”, LLC jointly with SarFTI NRNU MIPhI

in the frameworks of the The Foundation for the Assistance of Small Innovation Enterprises

(FASIE).

Goal of the project is demonstration of possibilities of new type of magnetic-pulsed

technology.